- Case Study Help

- Assignment Help USA

- HBD "Deloitte & Touche" Case Study Questions and Answer

HBD "Deloitte & Touche" Case Study Questions and Answer

Deloitte & Touche Consulting Group

June 14, 1995, was unseasonably warm and humid. Maria Chen, a senior consultant at Deloitte & Touche Consulting Group (Consulting Group), was halfway through a twelve-week engagement with SKS Manufacturing, a Pontiac, Michigan-based auto supplier. SKS had engaged the Consulting Group to reduce inventory levels in its main plant. After six weeks, however, work-in-process inventory had actually increased by 13%.

Early that afternoon, Chen had retreated from the shop floor to the relative calm of the second-floor conference room to pick up her messages and to briefly escape the stifling heat and throbbing noise from the floor below. She fell into the first available chair, leaned back, breathed in the coolness and tried to relax, but her concerns about the engagement interfered. To make things worse, she had been stopped on her way up by Jack Skidmore, the SKS president: He had tersely requested an explanation for the plant's lacklustre inventory improvements. She had no solid answer. She took a deep breath, picked up the phone, punched in her password, and felt her stomach tighten as she listened to not one but two urgent voice messages from David Hendry, the partner leading the project. She dialled the number he had left and listened to him say:

As she dropped the phone into its cradle, she realized she wasn't certain about what to do but thought there were probably two options. She could either build a presentation for the steering committee based on all the positive changes that occurred over the past six weeks (however, most of the evidence would be qualitative), or she could focus the next couple of days on trying to produce a noticeable reduction in inventory, which would be a long shot at best.

Deloitte & Touche Consulting Group

In 1995, Deloitte & Touche Consulting Group was officially designated a wholly owned subsidiary of Deloitte & Touche LLP. Deloitte & Touche LLP, known as one of the "big six" accounting firms, was formed in December 1989 by a merger between Deloitte, Haskins & Sells, and Touche Ross. Traditionally, Deloitte & Touche had been thought of as an audit and tax service firm, but at year-end 1993, the Consulting Group, which had a client base significantly different than the audit and tax practices, comprised 28% of the firm's total revenue. In the United States, the Consulting Group was comprised of 2,700 professionals (including 250 partners) and 5,600 consulting professionals worldwide.

The Consulting Group focused on delivering services in four main areas: operations, information technology, financial management and strategy development in a broad set of industries, including manufacturing, healthcare and financial services. In addition to the core, the Consulting Group teamed with its wholly-owned subsidiaries to deliver services. Those organizations included, Braxton Associates, a Boston-based strategy consulting firm; DRT International and CMD Systems, application and systems development firms. In 1995, the Consulting Group merged with ICS, a firm specializing in the implementation of large-scale SAP projects.

The Consulting Group’s primary competitors included Andersen Consulting, Price Waterhouse, Ernst & Young, as well as, McKinsey, BCG, Booz Allen and CSC Index. Industry-wide, the range of management consulting services could be described as a spectrum, with strategy consulting on one end and systems implementation on the other. The Consulting Group viewed its strength and position in the market as an "implementation" consulting firm. The firm's ability to offer a fully integrated strategy, operations, and information technology solution was key to its success.

Informative Blog for You: 120+ Informative Speech Topics and Ideas for Students in 2023

Learn everything about - How To Write an Argumentative Essay Outline

The Consulting Industry

Since the early 1990s, considerable transformation has occurred within the consulting services industry. Due to a number of factors, clients have become much more informed and demanding, which has resulted in the following:

- Integrated teams as late as the early 1990s; consultants often worked alone. Now, work teams almost always -include key client employees as well as consultants. This arrangement usually allowed both parties to learn from the other more effectively and help the client participate more fully in defining and implementing business solutions. At the same time, the breadth of personalities involved, their disparate backgrounds and a lack of common understanding of approaches could often add additional complexity to the situation.

- Knowledge transfer In the past, the norm had been to perform the agreed-upon services and then to move on once the consulting assignment was complete. However, clients began to realize that the benefits from their consulting investment were very short-lived unless its employees could carry on effectively where the consultants had left off. Clients expected critical knowledge to be transferred from the consultants to key employees. Teaching has become an integral part of successful consulting.

- Third-party ratings and the proliferation of consulting firms had fueled increased scrutiny and the birth of independent organizations that compiled evaluative reports and cross-industry ratings. The Gartner Group, for example, evaluated a range of factors, from success of implementations to "completeness of vision."

- Integration of approaches Clients were beginning to require consultants to have the ability and resources to develop and implement solutions that linked strategy to operations and technology more closely than they had in the past. Additionally, clients increasingly expected consultants to have industry-specific knowledge and the ability to provide solutions worldwide.

Career Progression

A new professional at the Consulting Group could expect his or her 'career to progress through the following levels, with a partner being the most senior position:

- Consultant/Analyst: While consultants performed many of the same tasks as the senior consultants, they generally lacked the experience level of their senior colleagues. Consultants were typically hired as undergraduates fresh from college. Although some consultants made their way through the ranks, many in this position chose to return to graduate school.., Analysts were also hired straight from undergraduate programs and were expected to provide the analytical support needed to make informed decisions during the engagement process. In addition, the Consulting Group hired Summer Associates, usually MBAs, between the first and second year of their coursework. Summer associates' responsibilities were similar to the senior consultants.

- Senior Consultants Senior consultants were usually hired from MBA programs, often with two or three years of industry experience. Major tasks included collecting and analyzing data, focusing and taking responsibility for particular sub-projects and presentations, facilitating and managing client teams and helping to prepare proposals for clients. An analyst often supported them.

- Senior Manager/Manager Senior 'managers dealt with the upper levels of client management, particularly with issues and problems that arose during the course of an engagement, and sometimes worked with multiple clients at one time. They also handled proposal presentations to prospective clients. Managers supervised several senior consultants on a single client engagement.

- Partner Just under 10% of the firm's consulting professionals earned this title, which generally took six to eleven years to achieve. As senior managers became partners, their focus shifted from the work involved in engagements to managing the client relationship. Partners typically handled two or three clients at once and focused on applying their experience to finding solutions and ensuring the client remained satisfied with the Consulting Group. Partners were also responsible for selling consulting group services and usually developed a specialization in a particular industry or service line.

No - fixed rules existed regarding progression up the ladder, but a framework of "expectations" outlined what professionals were expected to master in order to proceed. Professionals received appraisals at the end of each engagement. New hires with undergraduate degrees entered at the analyst or consultant level can expect to be promoted to senior consultants within approximately three years. New hires with graduate degrees or a minimum of five years of work experience were given the senior consultant title. Training for the new consultant was a combination of new hire/new position retreats and on-the-job training. The Consulting Group puts a great deal of emphasis on learning from doing.

Roughly two-thirds of new hires came from industry, with the remainder coming from universities like Harvard, Wharton, Chicago and Kellogg. About 75% of the latter category had advanced degrees (primarily MBAs) and, therefore, also had some prior work experience. Turnover at the Consulting Group was between 15 and 20% annually. The consultants who decided to leave the firm often cited a desire for a change in lifestyle or decided to join a client in management and executive positions. Additionally, some consultants left to apply their "implementation" skills in start-up businesses.

Check Out: How Many Pages is 500 Words?

SKS Manufacturing—the Client

The Company

SKS Manufacturing, a metal stamping manufacturer, was founded in 1959 by two General Motors-trained engineers, Allen Kramer and John Stefanski. SKS supplied a variety of exhaust system components to Tier 'I and Tier II suppliers, as well as after-market distributors. Since its founding, SKS has been completely tied to the automobile industry for better and for worse.

In the beginning, Kramer and Stefanski made the most of their "big three" connections and translated them into a solid and steadily growing business. In the early 1960s, a third partner, Robert Skidmore, came aboard. Skidmore, a renowned charmer, was able to win new contracts quickly and ultimately set the company on its current trajectory. Still privately held, Kramer's eldest son, Jack, was named president in 1989. Ownership was split between the. Kramer and Skidmore families; Stefanski was bought out in 1977. Since those early days, SKS had grown into a formidable competitor and a leader within its industry; 1995 year-end sales were projected to be just under $570 million, and SKS now employed over 5700 people.

The elder Skidmore had brought a vision to the company of industry leadership and sales figures that were far beyond his partners' original conservative projections and careful cash flow analysis. He firmly believed sales focus was the vehicle for long-term success, and he instituted an intact sales structure. SKS salespeople focused on direct sales and kept existing customers happy within Region I (Michigan--especially Metro Detroit, Ohio, and western Indiana). Manufacturing representatives were used to cover the rest of the United States and, to a small but growing degree, Mexico and Canada. Sales were heavily concentrated with three major customers, which comprised 65% of the total. SKS had only begun exporting in the last five years) and consequently only 3% of sales were outside of the U.S. The current generation of managers realized this would have to be changed to ensure ongoing viability.

Most Searchable Blog - What Are the Best Business Research Topics For 2023?

SKS's main plant was located in Pontiac, Michigan, an industrial suburb north of Detroit. The facility was 450,000 square feet, which gave the company ample capacity for the current volume plus a little room. to grow. Most of the manufacturing processes were performed at this location. Some items required special coatings and were shipped out to one or two nearby suppliers. One warehouse was also located on the premises, but a second was inconveniently located six miles to the south of this facility.

The SKS shop floor was a dingy, 'noisy place—smelling of the lubricating oil used to coat the metal to help it flow in the presses. In the press section, brake presses, making between 20 and 60 blows per minute, stamped out metal parts from raw sheet metal, then spat the newly trimmed components into a chute, which emptied into a wire cage bin on a pallet. The presses were drawn from a variety of vintages—from new, automatic presses with computer control to a few battered old WWII-vintage presses, with automatic guards incongruously retro-fitted. Testament to the bad old days of press work were the occasional old-timers who would shake one's hand absent a full complement of digits. In general, press work involved some vigilance for safety's sake but was primarily a machine-tending job. Over the previous few years, SKS had seen more pressure to change between components quickly as their product range grew and customer demand responsiveness strengthened. As a result of this, runs had become shorter and die-changes more frequent. Operators had become involved in this activity, but press-setting was still primarily a job for a skilled setter. Most people on the floor agreed that it was now a much better place to work than it had been but that it was still a little chaotic on occasion, with many components sitting between presses and "split-batches" making the job of keeping the production shop orderly very difficult.

SKS's new products were conceptualized and, for the most part, designed in-house. SKS had a full-time engineer pool of nine, with an average experience level of twelve years. The in-house design engineers used manual drawings and CAD applications. On occasion, for specialized applications, SKS would seek the help of an outside engineering and design firm.

Also, Read - How Many Pages Is 1500 Words?

Key Personnel

Most of the SKS management had been with the company for most of their careers and had fairly homogeneous backgrounds. SKS management stated that employees were treated "like family." Working well with the following people was important from the Consulting Group's perspective.

Jack Skidmore had been the SKS president since 1989. The eldest son of Robert Skidmore, he was, they said, "Molded in his father's image." So, quite naturally, he began a sales career after graduating from Central Michigan University in 1972 with a BA in history. He successfully worked for a few firms outside the family business (including- starting his own insurance agency) and then moved into the business thirteen years ago. Within SKS, he proved himself as a sales manager, tightening long term relationships that had begun to unravel with escalating industry competitiveness. Skidmore was known to "promise the world" and then somehow find a way to deliver. This behaviour solidified several teetering customer relationships but made his sales trips dreaded among the core group of workers that could be counted on to, in Jack's own words, "Make things shake." Often out of the plant on customer visits, Skidmore relied heavily on David Fletcher to run the day-to-day operations.

Trending Blog: Top 80+ Human Resources Research Topics

David Fletcher had been the SKS plant manager for the last eight years. With an engineering background and twenty-two years of experience in the automotive industry, Fletcher had joined SKS about fourteen years previously. Since then, he has held a variety of positions, including material "manager, production control manager, chief engineer and assistant plant manager. Fletcher was known as a hardworking and fair person, and although his temper could flare unexpectedly, he had won the respect of many SKS employees. He knew the plant inside and out and tolerated little less from his core management staff.

Stan Janovich was the first shift supervisor and had been for nearly nineteen years. Janovich was just a few years from retirement, and although he was looking forward to spending time at his northern Michigan cabin, he wondered aloud how things would continue to work without him around. He took great pride in his contributions to SKS and felt things were "pretty much in place." Janovich had been with SKS almost since its beginning and had seen the ebbs and flows of the auto industry, so, as he explained at the last staff meeting, things will "work themselves out."

The Engagement

SKS had sought out the help of a third party several months earlier. The company was experiencing a critical cash flow shortage and had delayed payment to several suppliers in order to service its payroll obligations. Additionally, SKS was unable to maintain acceptable customer service levels, shipping only 77% of customer orders in time to make the required delivery dates. By April 1995, SKS management realized it no longer had the luxury of time or the internal capability and focus to turn around the situation; they interviewed several consulting firms before ultimately engaging the services of the Deloitte & Touche Consulting Group.

The Consulting Group initially considered a longer-term "reengineering" approach that would focus on redesigning cross-functional business processes. This approach would be a radical change from the "functional silos" from which SKS currently performs business tasks. However, to begin with, the Consulting Group proposed a shorter and more focused twelve-week engagement that would stabilize the current cash position. The consultants advised that a radical "reengineering" approach, with the company in a cash crunch, might introduce a level of risk that the firm might not recover from. The Consulting Group viewed the twelve-week engagement as a necessary foundation to start the longer-term project, and SKS, with little previous experience with consultants, thought this would be a good time to "test drive" the firm.

The SKS project fell into David Hendry's line of responsibility, and Annette Wattley-Davis, a senior manager, would be second in command. Together, they selected a team of three consultants and two business analysts for the first 12-week project to stabilize operations. Additionally, they obtained a commitment from Jack Skidmore, David Fletcher, and Stan Janovich that they would spend at least 25% of their time working with the team.

READ BLOG: Research Paper Topics for Students in 2023

The engagement began in early May 1995

The Engagement Team

A typical Consulting Group engagement of this scope involves four to five professionals: a partner, a manager or senior manager, two to three senior consultants, as well as a couple of analysts. The team for the SKS engagement included the following people:

David Hendry was a partner based in the Detroit office. Hendry had the last eighteen years heavily involved in the automotive industry. He had worked with the three major automotive manufacturers and many major automotive part suppliers worldwide. An MIT-trained engineer, Hendry began his career as a design engineer at Ford. Motor Company, and after several years and an MBA from the University of Chicago, moved into the consulting world. He had been a partner for seven years, and his- concentration in this industry made him one of the Consulting Group's automotive "gurus." Hendry had recently taken on even greater responsibility for bringing in new business and was successfully shouldering his new load. Over the years he had acquired a reputation for results in the industry, which was a source of personal pride and continued motivation.

Annette Wattley-Davis' joined the Consulting Group as a senior consultant eight years ago, fresh from an MBA' at Wharton. Based in Cleveland, she has focused on business process reengineering for manufacturing firms for most of her Consulting Group tenure. As a manager, she was nominated by her local office to participate in a six-month national effort to develop a consulting group's next-generation reengineering for Results methodology. Since Wattley-Davis became a senior manager last year, she has focused almost exclusively on the automotive industry.

In addition to the SKS engagement, she was finishing up another project in Dallas that required between 2 and 3 days of her time over the first six weeks of this engagement.

Get Answer: Mystic Monk Coffee Scandal

Maria Chen worked for three years after finishing her BA in economics (Amherst'89) for General Electric as an associate in their management training program. In this program, she was exposed to many different areas of operations, including finance, internal audit, manufacturing, and engineering. At the Harvard Business School (MBA'94), Chen performed well academically and had a knack for quantitative analysis. After her arrival at the Consulting Group in August 1994, Chen reflected, "I came to this firm to get some diversified "hands-on" operations experience." Since that time, she has been undergoing training and assisting with various projects. SKS, although her second direct manufacturing experience, would be the first project where she was directly responsible for significant work pieces.

Ben Rohan and Ramesh Patel were the other two consultants on the engagement team. Rohan was an experienced senior consultant based in the Detroit office. He had a BS in computer science from the University of Illinois, an MBA from Dartmouth, and a number of years of procurement and manufacturing experience. Since he joined the Consulting Group last year, he has been on three different engagements: one in health care, one in financial services, and the last one in manufacturing. Patel joined the Consulting Group as a summer associate. A Cornell-trained engineer's objectives were to gain some practical client experiences and evaluate the Consulting Group as a future employer. The firm looked for Patel to be an active team member and to provide analytical support. The Consulting Group also wanted to recruit him for the following year.

Also, go through the interesting blog on 220+ Interesting Persuasive Speech Topics for Students.

The Planning Meeting

Wattley-Davis recognized that a multiple-pronged approach would be required to address SKS's short-term business and manufacturing problems. A quick analysis of the company's cost structure and inventory levels indicated that reducing cash investment in raw materials and synchronising production and procurement would alleviate the immediate problems.

About a week before the start date, she brought the team together to discuss the preliminary issues and to make sure everyone knew what they were expected to accomplish and were comfortable in their roles. One team would be led by the industry-hire Ben Rohan. His job was to attack the material procurement processes and raw material levels. Maria Chen led the second team. She would address the production scheduling processes and synchronize production operations with purchasing. They were expected to work together on this "quick hit" opportunity to reduce inventory.

Chen walked away from the meeting excited and was eager to begin the project. When she returned to her office, she reviewed her notes to ensure she knew exactly what she needed to accomplish over the next twelve weeks. As she saw it, her main goals were:

- To develop production scheduling rules and processes that would smooth production, relieve the most severe bottlenecks and reduce the number of crises the plant was experiencing, which would decrease the need for “buffer" inventory.

- To design and implement a pilot of a pull-based synchronous manufacturing cell in twelve weeks,' as well as a new factory layout design and roll-out plan;

- To work with Ben Rohan to reduce overall inventory levels by $10M within twelve weeks.

Additionally, the Consulting Group wanted to position itself for the larger reengineering opportunity and identify any further add-on work.

Interesting Topic on 90+ Best Marketing Research Paper Topics Ideas for You

Time Zero

Chen was very anxious to make a good first impression with the client. She had spent the weekend before reading up on synchronous manufacturing techniques and had placed a few calls to a few Consulting Group colleagues that she had heard worked on similar engagements. She flew into Detroit Metropolitan Airport the night before and was the first to arrive at the plant.

Upon arriving, Chen notified the receptionist that she was with the Deloitte & Touche Consulting Group reengineering team and, although early, asked to see the plant manager, David Fletcher. In a few minutes, Fletcher came into the lobby and approached Chen. She expected a warm welcome but realized immediately that either Fletcher was not pleased she was there or hadn't had his requisite caffeine intake that morning. After a perfunctory handshake, Fletcher wanted to know, "What exactly did she think she was doing there?." -Chen was shocked by the cold reception and Fletcher's lack of information and did not understand why Jack Skidmore had not informed Fletcher about the -start of the engagement, the use of consultants, and the scope of the project. Fletcher suggested Chen leave the plant site until he had time to sort the whole thing out.

Soon, the rest of the consulting team arrived in the lobby, and Chen relayed her story to Hendry and Wattley-Davis. Hendry phoned Skidmore, catching him on his way to the airport, and found Fletcher had just that day returned from a ten-day vacation. Skidmore agreed to smooth everything over, and the consulting group team entered the plant an hour and a half later. The engagement had begun, but Chen could not imagine a rockier beginning.

Check it Out: How Many Pages Is 2000 Words?

Ramp Up

Annette Wattley-Davis recognized that as a fairly new consultant, Chen was taking on a lot of responsibility and was thrown into a difficult and vague situation with this engagement. She spent some extra time with Chen, talking her through some of the issues she would likely run into in the next few weeks. Wattley-Davis relayed- lessons she had learned the hard way, for example, the importance of gaining consensus around new ideas and the difficulty of making changes on the factory floor. She also worked with Chen to develop a detailed work plan for her part of the project and suggested ways to integrate the work into the team's overall work plan.

The first week was hard but after the second week, Chen had started to settle into the SKS culture. The team had made a Spartan but comfortable conference room on the second floor of their headquarters. They spent the first few weeks there collecting data, creating a spreadsheet model of material flow, and eating late-night pizzas. The team had begun to work well together, and although Jack Skidmore and David Fletcher only spent parts of their work day with the consultants, they had begun to spend more time with them after hours. Chen was working at full speed on a complex spreadsheet model that she believed would "knock the socks off" both Wattley-Davis and their client. Because the spreadsheet turned out to be a bit more complex than she had first designed, she ended up having to sacrifice some of the other items on her list of things to do.

Also, get Topics on Engineering Research Paper Topics of 2023

At the end of the third week, the team members, including client team members, prepared summaries of their analyses and previewed them with selected plant staff members. In a group of eighteen, the team members individually presented their overheads. Chen's presentation on her material flow simulation did not go as well as anticipated. Stan Janovich, whom she had wanted to talk with earlier in the week (but had run out of time), pointed out many issues that had not been accounted for in the model. She grudgingly realized Janovich was completely on target with his criticisms and jotted some notes for the simulation revisions.

After the meeting, Wattley-Davis- took Chen aside and quizzed her about how much of the modelling effort had been reviewed with Janovich and other key people on the floor prior to the meeting. She also asked how much time she had actually spent on the factory floor and with the other team led by Rohan over the last few weeks. Wattley-Davis's displeasure was obvious as she suggested Chen move her workspace from the conference room to the factory floor. Chen dejectedly agreed, and as she turned away, the senior managers continued, “And, pull the plug on that spreadsheet for a while."-

Phase Two

By the end of the fourth week, Chen began to realize the value of her manager's mandate to move down to the shop floor. After staining and nearly ruining her new Donna Karan suit, she wore jeans and an equally replaceable shirt. Her first encounters with Janovich left her with the distinct impression that he was gruff, unapproachable, and not at all interested in the consulting group's work, but as she came to know him, she realized that was not completely true. She began to have casual conversations with him about his twin grandchildren (Nicole and Nicholas), the history of the plant, and eventually, how scheduling work was really done outside of the computerized program, which she had been briefed on.

She gradually learned that two sets of procedures were being followed daily—a formal documented process and the way work was done. Alterations from the formal process were sometimes for a shortcut and other times to avoid the computerized system, which many folks on the floor felt was useless. Chen also found that Janovich's opinion carried a lot of weight in the SKS world, even though he only held the title of day shift supervisor.

As she spent more and more time with Janovich, she realized he consistently "bad-mouthed" the sales group for dumping orders at the end of the quarter and changing the priorities of jobs once they had been launched. He also explained his computer mistrust; the bills of material and parts lists developed by engineering were always out-of-date. He pointed to a dented grey (and "rust") filing cabinet that contained marked-up parts lists and prints that were the Plant's "true" records. Janovich also admitted that inventory accuracy had always been a problem. Chen also discovered that in addition to poor data in the system, most of the applications were not integrated. Much of the basic data for an order had to be reentered when moving from order entry to the manufacturing system. Betty Ranowski a long-time SKS clerk, was responsible for re-keying the orders into the manufacturing system every Monday.

Solved: All of the following are steps in derivative classification except

Chen mentioned this new information to some of her teammates. They suggested she Meet with the sales, engineering, and information technology managers to contrast their points of view with Janovich's. This made sense to Chen, but she decided to stick closely to the directives given by Wattley-Davis--stay on the floor until you fully understand the production system. The memories of the first day and her sinking spreadsheet model seemed very fresh, and she was intent on redeeming herself as quickly as possible. She did, however, talk to the clerk, Betty Ranowski, about the time and effort required to re-enter all of the manufacturing orders.

During the fifth week, Wattley-Davis evaluated Chen's progress (versus- her original work plan) and asked again that she spend more time working with Rohan and key information technology people at SKS. By the week's end, Chen felt like things were back on track. She had “started to make some changes in the floor layout with Janovich's input. One of the major bottlenecks in material flow started to ease, and jobs seemed to be moving much faster. She began collecting data and posting the performance trends by stamping lines in a location where they couldn't be missed. The trend lines looked unchanged, and Skidmore had the charts showing poor on-time deliveries taken down just before a major customer was scheduled to tour the facility.

After the customer meeting and tour, Skidmore found Chen and asked for a quick update on the progress that was being made. He also expressed his concern that Chen was giving his employees the impression that the consulting group work at SKS meant some people were going to be fired. Chen was shocked to hear this, fumbled with her response, and ultimately promised to look into it. Skidmore, not seeming overly pleased, dismissed her and walked away. Chen was stunned and had no idea how something she had done could have resulted in such a conclusion. She later learned that her chat with Ranowski had been interpreted by Ranowski,' as "the beginning of the end.'',

"White Knuckle" Time

Chen sat tensely at the conference table and considered her options. She knew progress was being made, but not at the accelerated pace that she had initially envisioned. She also knew the steering committee meeting would be a showdown if she had no substantive improvements to show. She wanted desperately to show a major improvement in inventory reduction for her first six weeks of effort.

The performance metrics she had just graphed showed that although on-time delivery had improved slightly from 77% to 79%, the total work-in-process inventory had actually increased by 13%. She heard the warning words of Janovich ringing in her head. Maybe he was right. Maybe this business was unique, and inventory levels needed to be at a higher level, especially at the end of a quarter, to buffer the poor forecasts generated by sales.

Chen also reflected on Hendry's counsel two weeks earlier to start a formal change management and communications process, even during this project's first phase. She had that on her work plan, but she wondered if that would have really helped calm Ranowski's fears. How could she have jumped to the conclusion that she was going to get fired?

Also Read: Critics of the Wealth Gap Might Argue That

Deep down, Chen knew that she had made progress, even if the numbers didn't reflect the results. For the first time in the company's history, the individual managers were starting to act as a team and were taking a cross-functional view of their business. She had raised their awareness above the finger-pointing between functions for problems and complaints of the "stupid mainframe system" to focus on the underlying problems. Fletcher, who had nearly thrown her out of the plant the first day, was now .spending more time with her testing different plant floor layouts and trying to reduce work-in-process inventory.

Chen feared that if she didn't have the hard numbers, the project would be shut down before it could be successful. She also worried that the early termination of a strategically' important engagement would virtually eliminate her firm's ability to sell the larger reengineering engagement to this client. Finally, she believed that she had been placed in a very difficult position and that her evaluation would not accurately reflect the degree of difficulty of this situation and what she had accomplished.

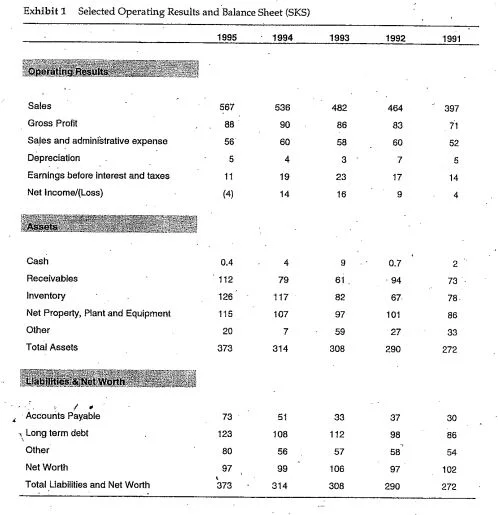

Exhibit T Selected Operating Results and Balance Sheet (SKS)

Exhibit T Selected SKS Products

HBD "Deloitte & Touche" Case Study Questions and Answer: AI & Plagiarism-Free

Ready to excel in your academics? Our expert writers provide high-quality, customized HBD "Deloitte & Touche" Case Study Questions and Answer to meet your unique needs. Take the first step toward success—contact us today for unmatched assignment assistance!

NEED ASSIGNMENT HELP?

Boost Your MBA Grade!

CDR for Engineers Career

Browse Similar Services

- Expert Assistance for Law Assignments and Homework Help

- Information Technology Assignment Help from IT Experts

- Finance Assignment Help

- Marketing Assignment Help

- Assignment Help Boston

- Assignment Help Los Angeles

- Assignment Help Chicago

- Assignment Help Houston

- Assignment Help Lawton

Get Expert Assistance!

Best Deals on Assignments!